Straightening barrels on AFV

Moderators: dnichols, GHQ, Mk 1

-

cabin4clw

- E5

- Posts: 104

- Joined: Mon Jan 03, 2005 5:45 am

- Location: West Michigan

Straightening barrels on AFV

Hi,

Can someone please let me know their technique on getting barrels straight? No matter how hard I try there is still a bend in them.

Joe

Can someone please let me know their technique on getting barrels straight? No matter how hard I try there is still a bend in them.

Joe

-

Donald M. Scheef

- E5

- Posts: 1629

- Joined: Sun Jun 25, 2006 2:24 am

- Location: Waukegan, Illinois USA

-

Ivan

- Posts: 58

- Joined: Sat May 21, 2011 8:51 pm

- Location: Dover,Pa.

-

Cav Dog

- E5

- Posts: 881

- Joined: Wed Dec 29, 2004 1:12 am

Flat nose or duck bill pliers are the best tool to straighten barrels. If there is no muzzle brake or bore evacuator you can GENTLY squeeze the barrel lengthwise while spinning the turret by the barrel between the jaws. If there is bore evacuator or muzzle brake you have to work in sections. Did I say gently?

Tactics are the opinion of the senior officer present.

-

AllenRockwell

- E5

- Posts: 381

- Joined: Fri Apr 29, 2011 1:47 am

- Location: Palm Springs, CA USA

- Contact:

Number 4 is what most of us end up settling upon as the final solutionDonald M. Scheef wrote:My technique:

1. Use fingers.

2. Use miniature pliers.

3. Give up before barrel breaks completely.

4. Live with barrels that are not absolutely straight.

Don S.

Allen Rockwell

Owner, GameCraft Miniatures

GHQ Fanatic since 1978

My Micro Armor Blog www.allensmicroarmor.com

Owner, GameCraft Miniatures

GHQ Fanatic since 1978

My Micro Armor Blog www.allensmicroarmor.com

-

Nazgul

- E5

- Posts: 343

- Joined: Thu Jan 13, 2005 1:24 pm

- Location: Mid Missouri

I agree with Allen, but before I give up I use a pair of stamp tweezers (looks like paddles on the end) with self adhesive felt applied to the inside. I slowly rotate the barrel and close the tweezers at each rotation. It does a fairly good job and doesn't leave any marks like the previous attempts with forceps or pliers. Worse case I hide it with camouflage  .

.

-

Mk 1

- E5

- Posts: 2383

- Joined: Fri Dec 24, 2004 3:21 am

- Location: Silicon Valley, CA

I use a rather particular set of tweezers I acquired several years ago.

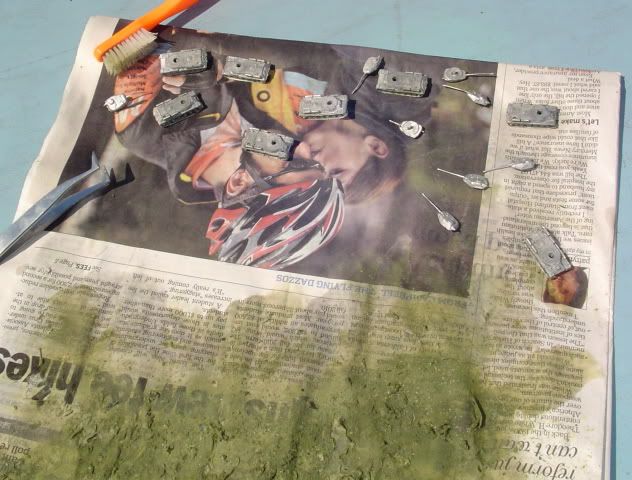

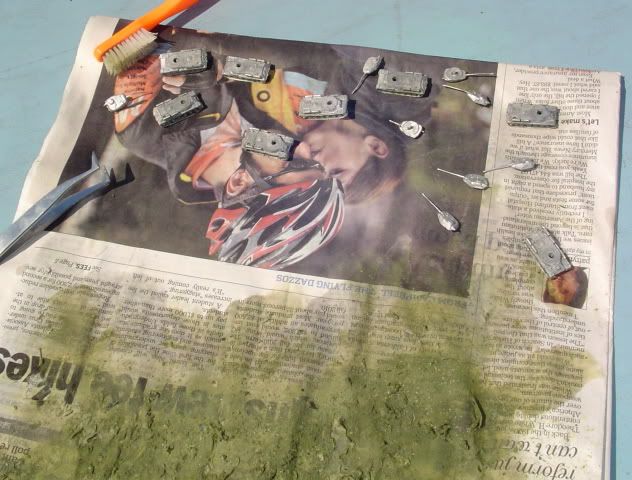

You can see them on the left side of the picture.

In this close-up you get a pretty good view of the flat-head on the tweezers.

I place a bent barrel between the two flat heads and squeeze gently. It supports the barrel while making two sides of the barrel parallel. Depending on the barrel and the bend, I sometimes have to turn the barrel and do it two or three times to get it very straight.

Here I am using the tweezers to hold a turret up for examination. After the picture I used the tweezers to straighten this barrel.

In a rather extensive refurbishment project on some old (pre-1990) GHQ IS-2s, there was only one barrel I was not able to save. That unit, seen in the top picture, was already broken.

Here is the whole set of IS-2s. My effort was not focused on straightening barrels, but rather stripping and re-painting the older models. So this is not my best effort on straightening -- the tweezers technique can do better. But even with just a fast once-over squeeze the results are much improved.

You can see them on the left side of the picture.

In this close-up you get a pretty good view of the flat-head on the tweezers.

I place a bent barrel between the two flat heads and squeeze gently. It supports the barrel while making two sides of the barrel parallel. Depending on the barrel and the bend, I sometimes have to turn the barrel and do it two or three times to get it very straight.

Here I am using the tweezers to hold a turret up for examination. After the picture I used the tweezers to straighten this barrel.

In a rather extensive refurbishment project on some old (pre-1990) GHQ IS-2s, there was only one barrel I was not able to save. That unit, seen in the top picture, was already broken.

Here is the whole set of IS-2s. My effort was not focused on straightening barrels, but rather stripping and re-painting the older models. So this is not my best effort on straightening -- the tweezers technique can do better. But even with just a fast once-over squeeze the results are much improved.

-Mark 1

Difficile est, saturam non scribere.

"It is hard NOT to write satire." - Decimus Iunius Juvenalis, 1st Century AD

Difficile est, saturam non scribere.

"It is hard NOT to write satire." - Decimus Iunius Juvenalis, 1st Century AD

-

Ivan

- Posts: 58

- Joined: Sat May 21, 2011 8:51 pm

- Location: Dover,Pa.

Hello , Comrades , Nice job on those OLD GHQ JS-2 tanks MK 1 . Redone mine almost two years ago. Took a look at your hobby/craft tweezers you use, I have a variety of those myself. The tweezers I use to straighten my bent barrels are basic tweezers that mostly every household uses. Just finishing up on some OLD GHQ Firefly's have to put some decals on them. Their barrels bent very easy if your not careful. Well keep up the nice work on your OLD GHQ ARMOR. Later Comrades , ( can't stand a bent barrel ) not nice when men don't take care of their toys , Have a Nice Day Ivan

-

busboy

- E5

- Posts: 100

- Joined: Mon Sep 10, 2012 5:18 am

Mk1 just explained my method to a T (to include the same exact set of tweezers). The only thing I can add is that I use a pinch of the fingers and a pulling motion to initially get the barrel "close enough" so the tweezers can do the rest.

I did have one M4A1 (76) that came out of the box without a complete gun tube. I chopped it off, drilled a small hole, glued an appropriate guage needle inside the hole, and clipped it to length with a wire cutter. It isn't as detailed as the case gun of course, but definitely passable, especially since on that particular model there is no muzzle brake, etc. Definitely keep that in mind if worse comes to worse.

I did have one M4A1 (76) that came out of the box without a complete gun tube. I chopped it off, drilled a small hole, glued an appropriate guage needle inside the hole, and clipped it to length with a wire cutter. It isn't as detailed as the case gun of course, but definitely passable, especially since on that particular model there is no muzzle brake, etc. Definitely keep that in mind if worse comes to worse.

-busboy

-

Mk 1

- E5

- Posts: 2383

- Joined: Fri Dec 24, 2004 3:21 am

- Location: Silicon Valley, CA

Well, if we are on the topic of replacing gun barrels ...busboy wrote: I chopped it off, drilled a small hole, glued an appropriate guage needle inside the hole, and clipped it to length with a wire cutter. It isn't as detailed as the case gun of course, but definitely passable ...

In that same refurb project, as you can see at the top, one of the barrels was already broken when I started. (These old IS's have seen a LOT of action over their decades-long service life!)

Here is what I did to replace the broken barrel:

My choice for replacement barrels is the plastic binder strings used to hold price tags on new clothes. They come in a variety of sizes and lengths. Almost all have a step-down in diameter somewhere along their length, which greatly simplifies replacing telescoping compound-barrels. I have about 40 of them that I have collected, just by keeping them whenever new clothing items are bought. They are really pretty straight, yet they are entirely flexible and spring right back into shape. So once a barrel is replaces, it will never get bent again.

As busboy said ... snip the old stub off. Do a bit of drilling (I use a thumb drill in many cases, although for barrels I often just use a needle and spin it around a bit). Snip your replacement barrel to length, put a dab of super glue (cyanocryllate) on it, insert it, and hold for a few seconds (I use gel rather than liquid super glue. Takes a bit longer to set, but I find it easier to work with if it doesn't flow away from where I put it.).

In the picture, I have not yet cleaned off the excess glue from the mantlet.

Then I put a bit of gel on the end of the barrel and give it a quick squeeze with the tweezers (quick - clean them off!), to make a muzzle brake.

Now go back to the pic with all the finished refurbs in my prior post, and just try to figure out which refurb'd IS-2 has the replacement barrel!

-Mark 1

Difficile est, saturam non scribere.

"It is hard NOT to write satire." - Decimus Iunius Juvenalis, 1st Century AD

Difficile est, saturam non scribere.

"It is hard NOT to write satire." - Decimus Iunius Juvenalis, 1st Century AD